Innovative sediment management in hydropower

Storage hydropower plants in the Alps play a major role in the electricity supply. However, sedimentation reduces their storage capacity year after year, which can also lead to safety issues at dams. ETH researchers and power plant operators are examining the effects of diverting fine sediments via the turbines.

Given the risk of supply shortages in winter and the demands on the future energy system, the existing hydropower capacities must be maintained as a matter of urgency. To achieve this, the deposits must be removed regularly, either by flushing the reservoir or by conventional dredging. However, both methods result in production losses and are therefore expensive.

Sediment removal via the power waterway

One method that is still little used and researched is the transport of fine sediments through the power waterway, meaning they are carried with the water flow through the turbines. This approach is currently being investigated in a research project conducted by the ETH Laboratory of Hydraulics, Hydrology and Glaciology under Prof. Robert Boes, in collaboration with illwerke vkw AG, an Austrian energy company. In addition to the technical factors, economic aspects and environmental regulations must also be taken into account.

The test site is the Bolgenach reservoir in Vorarlberg, located in an area with geologically soft rock and is therefore heavily affected by sediment erosion. To control the sediments, a floating dredger is used to remove them from the reservoir. On board, the sediment is sorted, with the coarser material being transported below the dam using a purpose-built, energy-generating material ropeway and returned to the river. This also has an ecological benefit because the deposited material remains in the riverbed.

As little turbine abrasion as possible

The fine sediment fractions, making up more than 90% of the volume, are intentionally directed into the power waterway, where they are discharged via the turbines at the Langenegg power plant. However, this is not quite as trivial as it may sound, because the particles leave their mark on the turbines, causing hydroabrasive erosion. This method of discharge via the turbines is rarely practised up until now, and the impact on Francis turbines has been little researched. This is precisely where Prof. Boes' research team and doctoral candidate Carolin Friz come in.

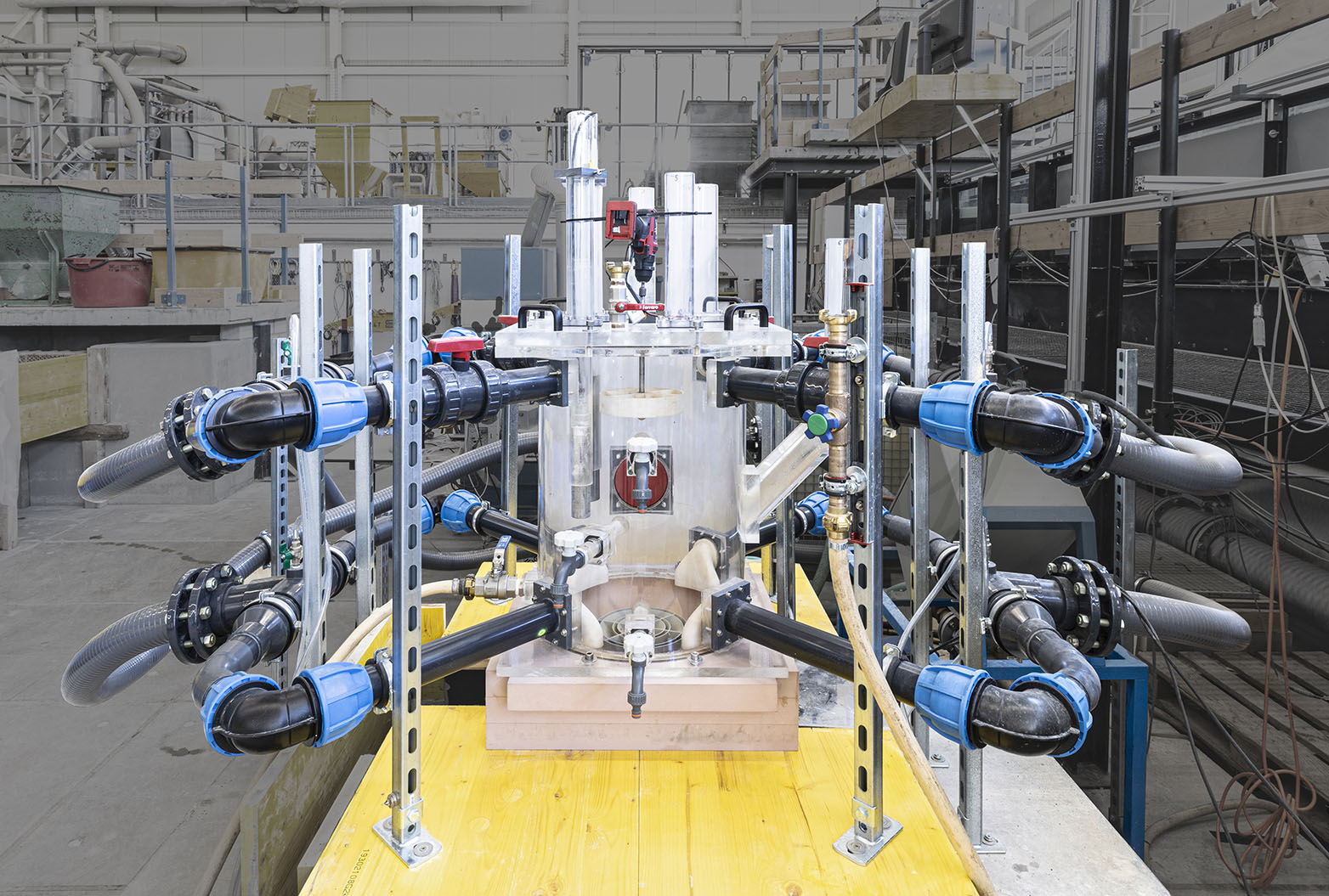

The advantages and disadvantages of individual sensor types for measuring suspended particles were evaluated in advance at the researcher’s test hall and laboratory. This helps reduce uncertainties during field monitoring. This is important because reliable real-time data is needed to optimise plants and comply with environmental limits. The aim is to measure the wear on various turbine components.

To this end, the team recently attached measuring gauges to the turbines to obtain various data – a difficult undertaking, since Francis turbines are not easily accessible. At the same time, illwerke vkw installed laser scanners that provide additional data. Important measurements are taken at least twice with different methods to detect and compensate for errors or failures. The level of abrasion on the turbines, both on the coating and on the steel, is now measured at regular intervals. The ratio between abrasion and sediment quantity, sediment concentration and particle size is determined. Depending on the results, the sediment supply is periodically adjusted to determine the optimal mix. This project should make a significant contribution to research into the relationship between sediment quantity, characteristics and abrasion.

A win-win cooperation for both partners

“It is very important for us to be able to implement the methods we have developed in the test hall in a real power plant. We hope to gain important insights that will lead to the further development of an abrasion model that would also be internationally significant for forecasting purposes,” says Prof. Boes.

Stefan Pfeifer, sediment management expert at illwerke vkw, explains: “Based on the findings, we decide what optimisation measures are necessary to ensure the long-term transport of fine sediments through the power waterway. This could range from adjustments to the coating to the type or even the geometry of the turbine.”

The project will continue until 2027 and is also supported by the Swiss Federal Office of Energy and the Crescere Foundation Thurgau. Both partners value the collaboration and hope to gain insights that will help them advance economically and scientifically.