ETH ALIVE (Advance Engineering with Living Materials) brings together researchers from different disciplines to develop new materials for a wide range of applications. The spectrum ranges from medicine, biotechnology, and materials science to robotics, climate-relevant research, and materials development. In addition to building a state-of-the-art research infrastructure, a key goal of the initiative is to promote young scientists.

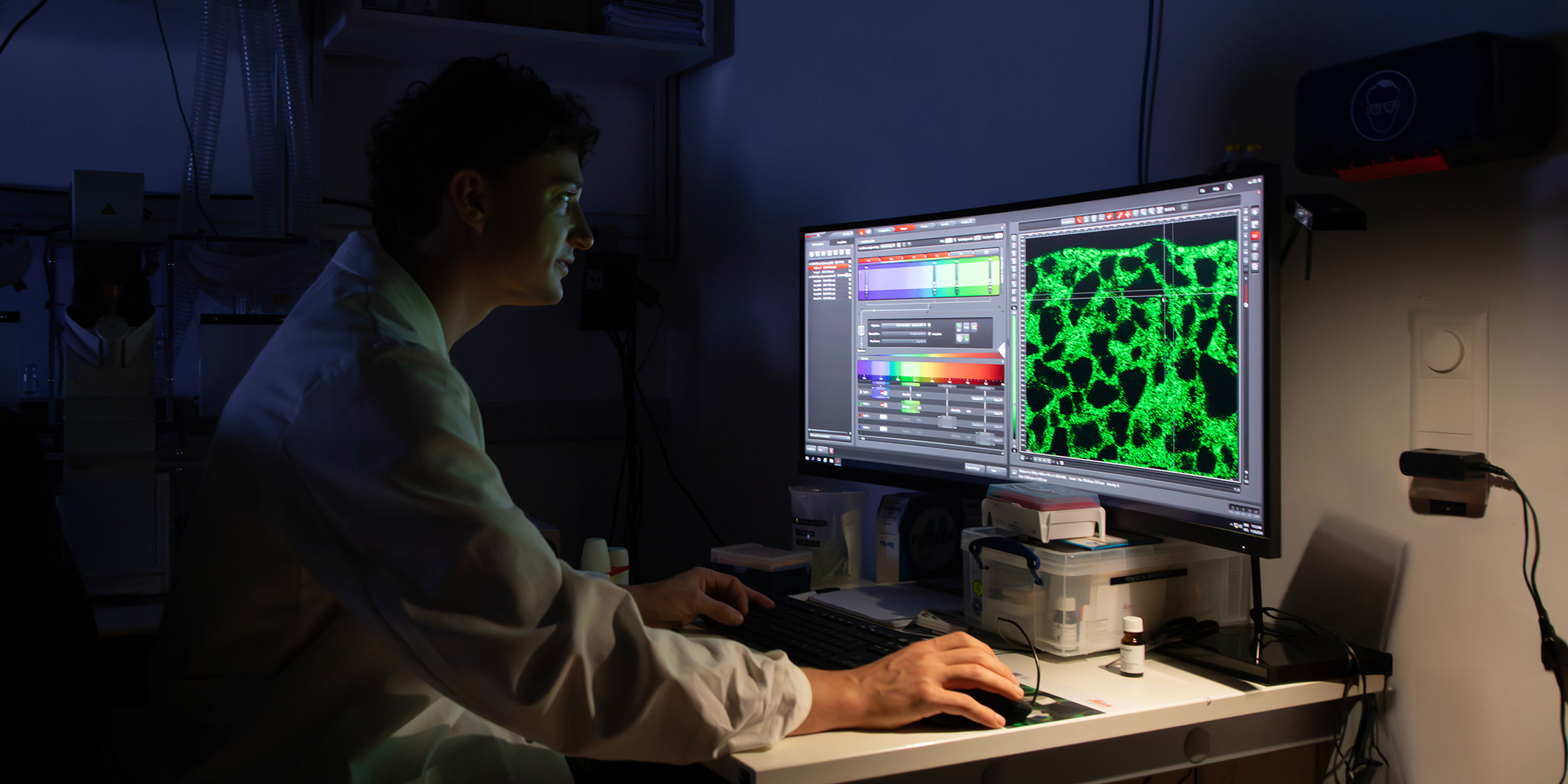

At D-BAUG, the research groups of Eleni Chatzi, Ueli Angst, and Ingo Burgert, together with their ALIVE fellows, are part of the interdisciplinary ETH initiative. The first ALIVE Symposium with external experts took place at the beginning of the autumn semester, where results of the first program phase (2021-24) were presented. In this context, D-BAUG News spoke to doctoral student Robert Kindler from the Chair of Wood Materials Science (ETH and Empa).

Robert, what exactly are living materials?

Living materials typically consist of two components: living organisms such as fungi or bacteria, which can be programmed to perform specific functions, and a carrier material that hosts these organisms. The organisms are utilized for their metabolic properties. For one thing, microorganisms can be more energy-efficient in producing complex substances; for another, different organisms can respond differently to external influences. We try to harness these functions to develop materials with unique properties that might go beyond the possibilities of conventional, non-living materials. Examples include the ability to self-heal in the event of damage and to detect or react to environmental influences.

But isn’t it easier to produce such new materials in industry?

In fact, when it comes to developing materials, a lot can be learned from nature. That’s why, in recent years, more and more researchers worldwide have begun investigating the potential of bacteria, algae, or fungi to act as “tiny factories” for the more sustainable production of complex materials. This refers to organisms being extremely efficient producers at ambient temperature and under normal pressure of complex materials such as bones, muscles, membranes, etc. In contrast, traditional manufacturing processes often need to work at very high temperatures, under high pressure, using solvents and the like.

What are the challenges of working with living materials?

The biggest challenge when working with living organisms is controlling and directing them so that they perform the intended processes consistently. That’s why we often have to optimize various conditions – like temperature, pH value, and nutrients – to ensure that the organisms behave as intended. Upscaling these processes is an additional challenge. While microorganisms are very efficient at producing materials in the micrometre range, it can be very difficult to keep these processes stable for larger dimensions.